When Should You Switch To A Spiral Helical Cutterhead?

Share

When to Upgrade from Straight Cutterheads to Helical Spiral Cutterheads: A Comprehensive Guide

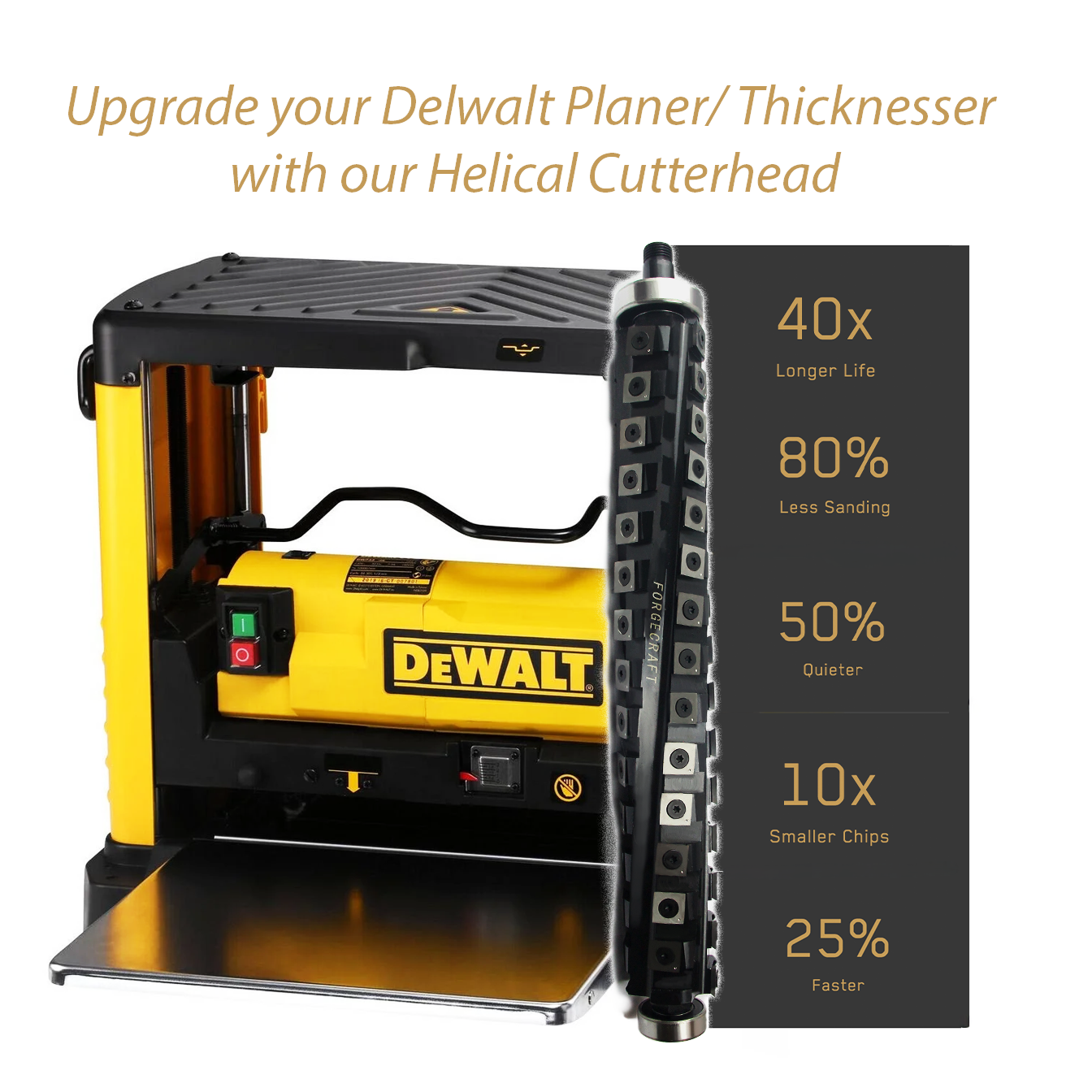

In the world of woodworking, the right cutter head can make a world of difference in the quality of your work and the efficiency of your equipment. If you’re still using a straight cutter head, you might be wondering if it’s time for an upgrade. Helical spiral cutter heads have become a popular choice among woodworkers for their numerous advantages, but is it the right move for you? Let’s explore when and why you might want to consider making the switch.

Understanding the Basics

Straight Cutter Heads:

- Design: Consist of a single, straight blade or multiple straight blades arranged parallel to each other.

- Operation: Cut the wood in a chopping action, removing material in a more aggressive manner.

- Common Issues: Can lead to rough finishes, increased noise, and more frequent maintenance.

Helical Spiral Cutter Heads:

- Design: Feature blades arranged in a helical or spiral pattern around the cutter head.

- Operation: Provide a shearing cut by engaging the wood at multiple angles, resulting in a smoother finish.

- Advantages: Known for quieter operation, reduced tear-out, and longer-lasting performance.

Signs It’s Time to Upgrade

- Quality of Finish:

If you’re noticing that your projects are requiring more sanding or finishing work to achieve a smooth surface, it might be time to consider a helical spiral cutter head. The shearing action of spiral blades produces a finer, cleaner cut compared to the chopping action of straight blades. This can save you time and effort in post-processing and result in a higher-quality finish on your workpieces.

- Noise Levels:

Straight cutter heads can be quite noisy due to the impact of the blades hitting the wood. If you find the noise levels in your workshop to be disruptive or bothersome, upgrading to a helical spiral cutter head could be beneficial. The staggered arrangement of spiral blades minimizes noise by engaging the wood more gradually, leading to a quieter cutting experience.

- Dust Collection Efficiency:

Straight cutter heads often produce larger, irregular wood chips that can clog dust collection systems and lead to inefficient extraction. Helical spiral cutter heads produce smaller, more uniform chips that are easier to collect and manage. If you’re dealing with frequent blockages or inefficiencies in your dust collection system, a helical cutter head could improve overall performance.

- Blade Maintenance:

If you’re spending a lot of time maintaining and sharpening your straight blades, it might be worth considering a helical spiral cutter head. Helical heads use carbide inserts that last significantly longer than traditional high-speed steel (HSS) blades. The inserts are also easily rotatable, meaning you can use each blade edge multiple times before needing a replacement. This can reduce maintenance time and costs over the long term.

- Performance with Hardwoods:

Working with hard or figured woods can be challenging with straight cutter heads, which may struggle with tear-out and snipe. Helical spiral cutter heads excel with these materials due to their shearing cut, which reduces the likelihood of tear-out and produces a cleaner result. If you frequently work with challenging woods, upgrading to a helical spiral cutter head can enhance your results and improve your workflow.

Benefits of Helical Cutterheads

- Enhanced Surface Finish:

- The shearing action of spiral blades delivers a smoother surface, reducing the need for additional sanding and finishing.

- Quieter Operation:

- The staggered blade pattern minimizes noise, creating a more pleasant working environment.

- Improved Dust Collection:

- Smaller, uniform chips are easier to manage, leading to better performance of dust collection systems.

- Longer Blade Life:

- Carbide inserts in helical cutter heads last longer and are easily rotatable, reducing the frequency of replacements and sharpening.

- Better Performance with Hardwoods:

- Spiral blades handle tough and figured woods more effectively, minimizing issues like tear-out and snipe.

In Conclusion

Upgrading from a straight cutterhead to a helical spiral cutterhead can be a game-changer for many woodworkers. The benefits of improved surface finish, reduced noise, and enhanced dust collection make it a worthwhile investment, especially if you’re dealing with challenging materials or looking to streamline your workflow. By considering the signs and benefits outlined above, you can make an informed decision and take your woodworking to the next level.