Spiral Cutterhead vs Helical Cutterhead: The Subtle Differences Make All The Difference

Share

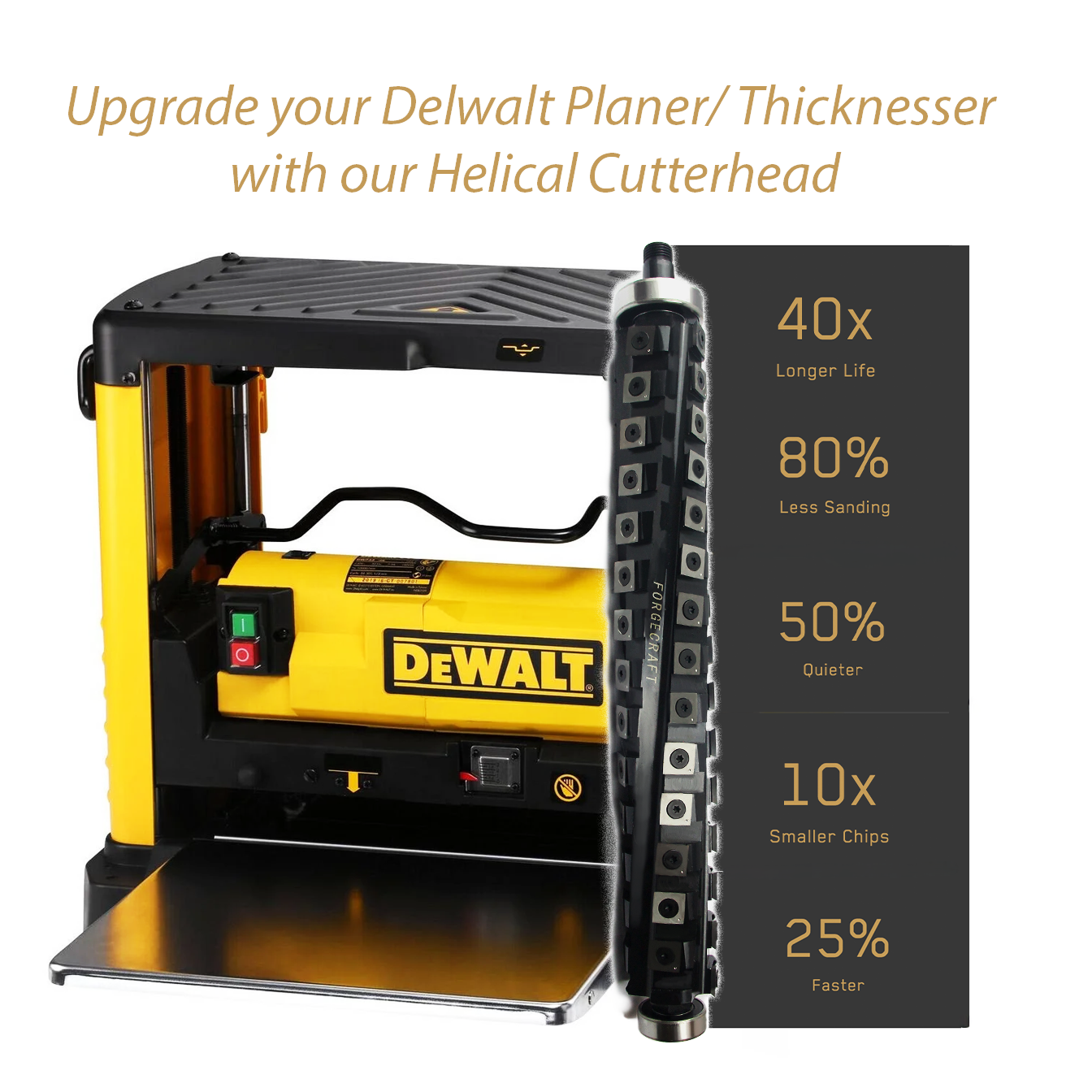

Spiral Cutterheads vs. Helical Cutterheads: Key Differences and Why You Should Opt for Helical Cutterheads

When it comes to upgrading your woodworking tools, the type of cutter head you choose can have a significant impact on your results and workflow. Two popular options are spiral cutter heads and helical cutterheads. While they may sound similar, they offer distinct differences that can affect everything from cut quality to maintenance. In this article, we'll explore the key and subtle differences between these cutterheads and why helical spiral cutter heads are often the superior choice.

Understanding Cutterhead Types

Spiral Cutterheads:

- Design: Spiral cutter heads feature blades arranged in a helical pattern around the cutter head. These blades typically do not overlap and are usually set at the same angle.

- Operation: As the cutter head rotates, each blade engages the wood at a different point, but the cutting action is still relatively direct.

- Cut Quality: Provides a smooth cut, though not as refined as helical spiral cutter heads. Some tear-out and noise may still be present, especially when working with hard or figured woods.

Helical Cutterheads:

- Design: Helical spiral cutter heads also feature blades arranged in a helical pattern, but they have a more advanced design where the blades are staggered and set at multiple angles. This arrangement allows for a more gradual and shearing cut.

- Operation: The staggered blade pattern engages the wood at various angles, resulting in a smoother, more consistent cut.

- Cut Quality: Excellent surface finish with minimal tear-out and reduced noise. Ideal for a wide range of materials, including hardwoods and figured woods.

Key Differences Between Spiral and Helical Cutterheads

1. Blade Arrangement and Cutting Action:- Spiral Cutterheads: Typically feature blades arranged in a straightforward spiral pattern. While this design improves upon traditional straight blades, it doesn’t offer the same level of refinement as helical designs.

- Helical Cutterheads: Employ a more sophisticated blade arrangement with staggered and angled blades. This design creates a shearing effect that results in a smoother surface and less tear-out, especially with challenging materials.

- Spiral Cutter Heads: Can be relatively noisy due to the direct engagement of blades with the wood. The noise level can be noticeable, particularly when dealing with dense or hard woods.

- Helical Cutterheads: Are significantly quieter. The staggered blade pattern reduces the noise by engaging the wood more gradually and evenly. This makes for a more pleasant working environment and reduces hearing strain over prolonged use.

- Spiral Cutter Heads: Provide a good surface finish, but some tear-out and snipe can occur, particularly with difficult grains and hard woods.

- Helical Spiral Cutter Heads: Deliver an exceptional surface finish with minimal tear-out. The shearing action of the blades cuts through the wood cleanly, reducing the likelihood of defects and requiring less post-processing.

- Spiral Cutterheads: Blades can become dull over time and may require frequent sharpening or replacement. The blades may also need to be rotated or adjusted regularly.

- Helical Cutterheads: Use carbide inserts that are long-lasting and easily rotatable. Each blade has multiple cutting edges, so when one edge becomes dull, you can simply rotate to a new edge. This reduces maintenance time and the frequency of blade replacements.

- Spiral Cutterheads: Produce larger, irregular chips that can be challenging for dust collection systems to handle effectively.

- Helical Cutterheads: Generate smaller, more uniform chips that are easier for dust collection systems to manage, leading to better overall shop cleanliness and efficiency.

Why Helical Cutterheads Are Often the Superior Choice

- Enhanced Cut Quality: The advanced blade design of helical spiral cutter heads provides a smoother, cleaner cut with reduced tear-out and less need for finishing.

- Quieter Operation: The staggered blade pattern reduces noise, creating a more comfortable working environment.

- Reduced Maintenance: The use of durable carbide inserts that are easily rotatable means less frequent replacements and sharpening, saving time and effort.

- Improved Dust Collection: Smaller, consistent chips improve the effectiveness of dust collection systems, leading to a cleaner workspace.

Conclusion

When choosing between spiral and helical spiral cutter heads, the decision often comes down to the specific needs of your woodworking projects and your preferences for maintenance and performance. While spiral cutterheads offer improvements over traditional straight blades, helical cutterheads provide superior results in terms of cut quality, noise reduction, and ease of maintenance. For the best overall performance and efficiency, opting for a helical spiral cutter head is usually the most prudent choice. With their advanced design and numerous benefits, they are well worth the investment for any serious woodworker looking to enhance their craft.