Helical Spiral Cutterheads: A Deep Dive

Share

The Engineering Mastery Behind Helical Spiral Cutter Heads: A Deep Dive into Design and Precision

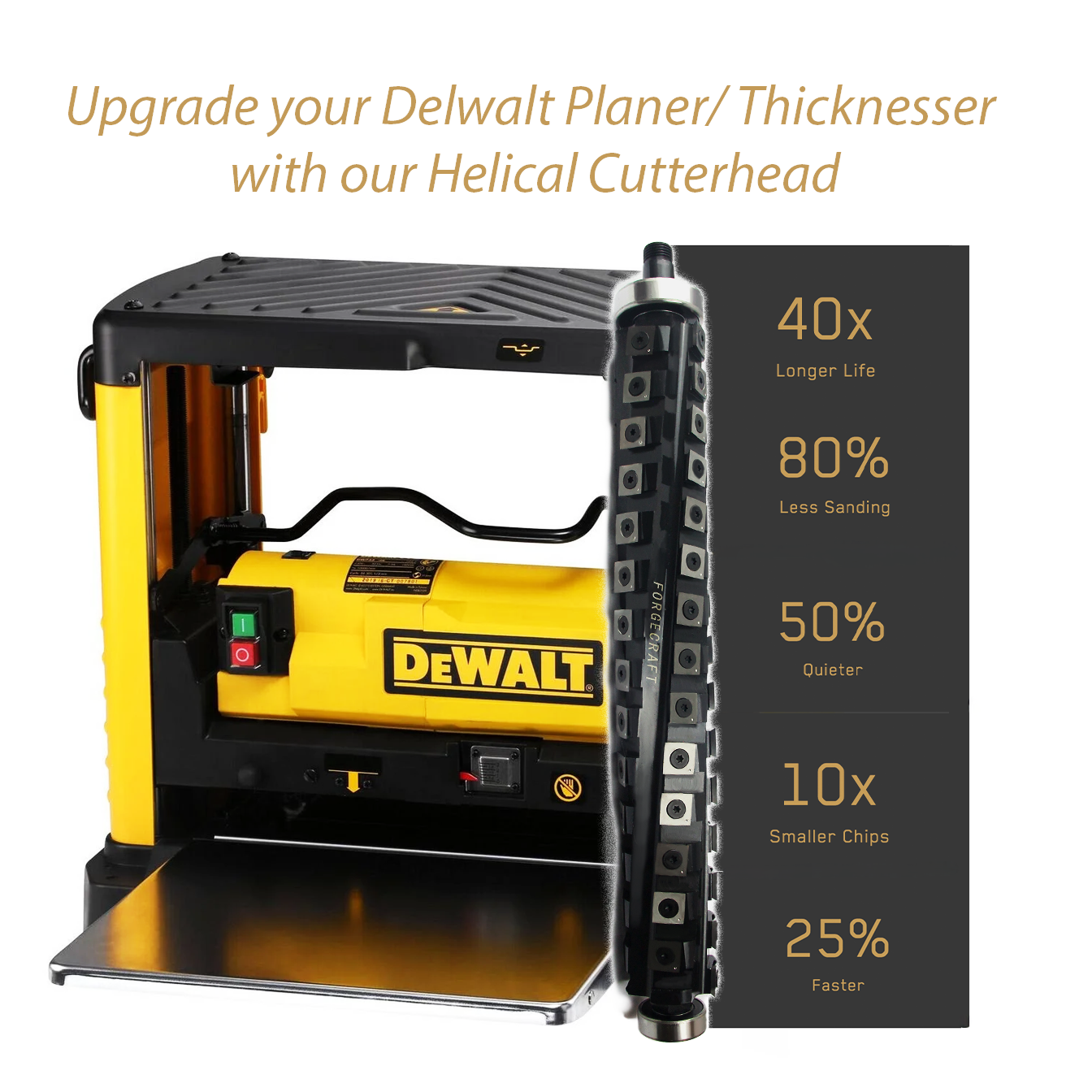

Helical spiral cutter heads represent a pinnacle of engineering and design in the world of woodworking. Their complex construction and precision machining not only enhance cutting performance but also significantly improve the overall efficiency and quality of the woodworking process. This article explores the intricate design of helical spiral cutter heads, focusing on the engineering principles, machining accuracy, and key design elements that make them a superior choice for woodworkers.

1. The Fundamental Design of Helical Spiral Cutter Heads

At its core, a helical spiral cutter head is engineered to provide a smooth, continuous cutting action through a spiral arrangement of blades. Unlike traditional straight blades, which engage the wood in a series of abrupt cuts, the helical spiral design employs a helical pattern that distributes the cutting force more evenly across the workpiece. This results in a smoother finish, reduced noise, and minimized tear-out.

1.1. Spiral Helical Arrangement

The helical spiral cutter head features blades arranged in a spiral or helical pattern around the cutter body. This design ensures that multiple cutting edges are engaged with the wood simultaneously, providing a consistent and efficient cutting action. The angle of the spiral and the number of rows of blades are meticulously engineered to optimize cutting performance and minimize vibrations.

The spiral arrangement also contributes to reduced noise levels. As each blade engages the wood at a slightly different point in the spiral, the cutting action becomes more gradual, resulting in quieter operation compared to traditional straight blades. This design feature is particularly valuable in woodworking environments where noise reduction is crucial.

2. Precision Machining and Engineering

The design and construction of helical spiral cutter heads involve advanced precision machining and engineering techniques. Achieving the high level of accuracy required for these cutter heads involves several key processes:

2.1. CNC Machining

The cutter head is typically manufactured using Computer Numerical Control (CNC) machines, which provide exceptional precision and repeatability. CNC machines can create the helical grooves and spiral pattern with tight tolerances, ensuring that each blade is positioned accurately. This level of precision is critical for maintaining consistent cutting performance and extending the lifespan of the cutter head.

2.2. Blade Seating and Alignment

The seats for the carbide inserts or blades are designed with exacting standards. Each seat must be precisely machined to ensure that the blades fit securely and align perfectly. This involves creating exact slots or pockets for the blades, often with a slight taper to facilitate proper seating and secure retention. The accuracy of these seats is crucial for maintaining the alignment of the blades and ensuring optimal cutting performance.

2.3. Material Selection and Treatment

The materials used in the construction of helical spiral cutter heads are selected for their durability and performance characteristics. High-quality steel or aluminum alloys are commonly used for the cutter head body, while carbide inserts are chosen for their hardness and wear resistance. The cutter head may also undergo various treatments, such as heat treatment or coating, to enhance its strength and resistance to wear and corrosion.

3. Spiral Rows and Cutting Performance

The number of spiral rows and the specific arrangement of the blades play a significant role in the cutting performance of the helical spiral cutter head. These factors are engineered to achieve the following benefits:

3.1. Optimal Cutting Efficiency

The number of spiral rows impacts the cutting efficiency and finish quality. A greater number of rows allows for more cutting edges to engage the wood simultaneously, which can improve the smoothness of the finish and reduce the load on each individual blade. This design also helps in reducing the amount of material removed in each pass, resulting in a finer cut.

3.2. Reduced Vibration and Noise

The staggered arrangement of the blades in the spiral pattern helps in reducing vibrations and noise. By distributing the cutting forces more evenly across the cutter head, the helical design minimizes the impact on the workpiece and the machine. This results in a smoother operation and less wear on both the cutter head and the machine.

3.3. Enhanced Dust Collection

The design of the helical spiral cutter head also aids in efficient dust collection. The smaller, more consistent chips produced by the spiral blades are easier to collect and manage compared to the larger, irregular chips from straight blades. This contributes to a cleaner working environment and more efficient dust extraction.

4. Maintenance and Blade Replacement

One of the notable advantages of helical spiral cutter heads is their ease of maintenance. The blades or inserts are typically mounted in a way that allows for simple replacement or rotation when they become dull. This modular design reduces downtime and maintenance costs, as individual blades can be replaced without disassembling the entire cutter head.

4.1. Blade Rotation

Carbide inserts in helical spiral cutter heads are designed with multiple cutting edges. When one edge becomes dull, the blade can be rotated to use a fresh edge, extending the overall life of the blade. This feature is particularly advantageous for maintaining consistent cutting performance and reducing the frequency of blade replacements.

Conclusion

The design of helical spiral cutterheads represents a sophisticated blend of engineering precision, advanced machining, and material science. The spiral arrangement of blades, combined with precise machining and high-quality materials, results in a cutting tool that offers superior performance, reduced noise, and extended blade life. For woodworkers seeking to achieve exceptional results with greater efficiency, the helical spiral cutter head stands as a testament to the advancements in woodworking technology and design.